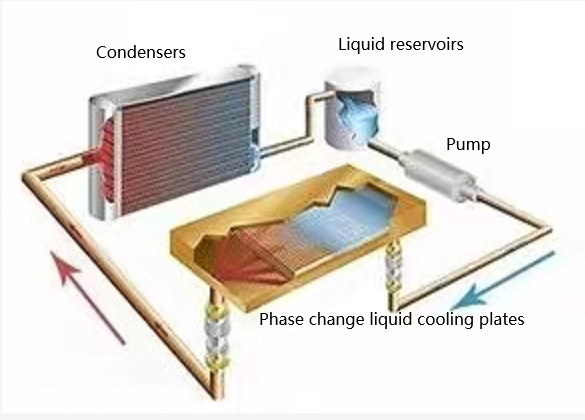

Phase change plate cooling is an indirect liquid cooling technology, i.e. the working fluid does not come into direct

contact with the heat generating parts, the technology uses a gas-liquid phase

change of the refrigerant with a lower boiling point to absorb heat from the

server. The working principle is shown in Figure 1, where the working liquid in

the plate absorbs the heat emitted by the processor and evaporates into a gas,

which condenses back into a liquid in the condenser and is then pumped back

into the plate. In many cases the plate is in the form of a heat pipe.

There are three main levels of heat

dissipation in data rooms: room-level heat dissipation; cabinet-level heat

dissipation; and server-level heat dissipation. Generally speaking, the closer

the heat sink is to the heat source and the fewer the number of stages of heat

transfer, the more efficient the heat sink will be.

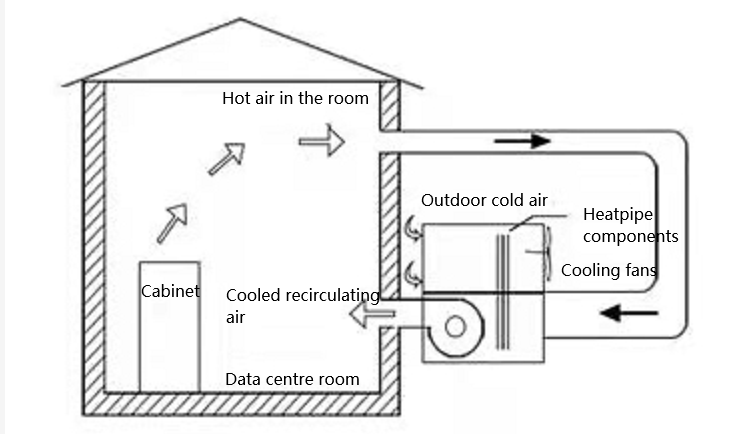

Phase change liquid cooling plate

technology at the server room level is heat pipe air conditioning technology,

as shown in Figure 2, where hot air flows through the hot side of the heat pipe

air conditioning unit and is processed to the right temperature, humidity and

cleanliness by the heat pipe heat exchanger before being reintroduced into the

server room for the next cycle.

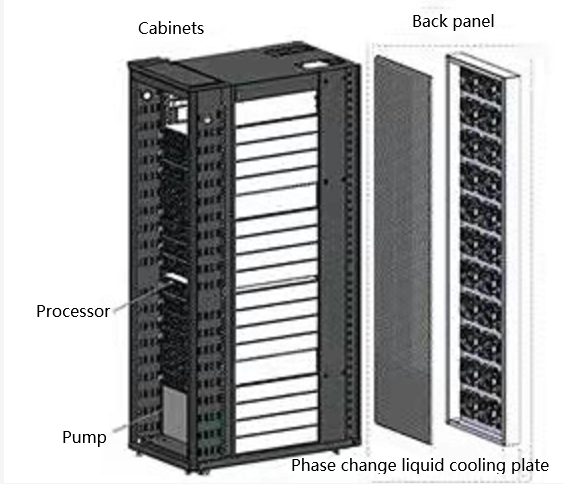

The main implementation of a cabinet-level

cooling system is the heat pipe backplane, which integrates the cooling source

into the cabinet, as shown in Figure 3, where a finned heat pipe heat exchanger

is integrated into a single plate, with the working fluid in the evaporation

section of the backplane absorbing heat from the processor to evaporate into a

gaseous state and condensing the working fluid into a liquid state via external

ventilation in the condensation section. The heat pipe is closer to the main

heat dissipation components, so its heat dissipation efficiency is higher

compared to heat pipe air conditioning technology. ZTE is actively researching

and developing single-phase liquid cooling technology and two-phase liquid

cooling technology. Laboratory data for single-phase liquid cooling technology

can reach a cooling capacity of 2,500W/slot, and two-phase liquid cooling (heat

pipe backplane) cooling can reach a cooling capacity of 5,000W/slot.

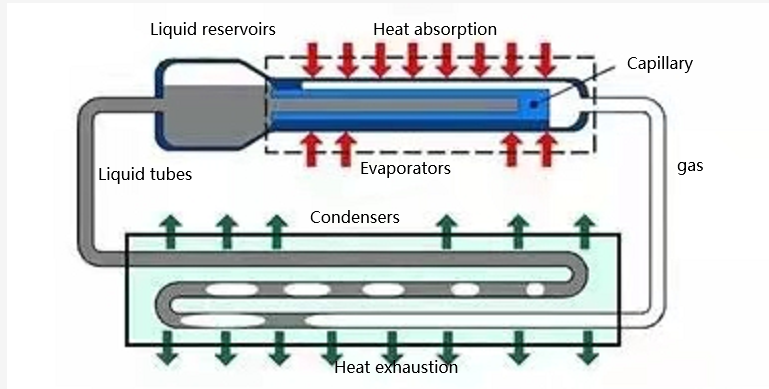

A company has applied loop heat pipes to server-level cooling systems, as shown in Figure 4, to increase the heat transfer area of the heat sink through the high heat transfer characteristics of the heat pipes. Due to the small distance between the heat pipes and the processor, the evaporative section of the heat pipes directly absorbs the heat emitted by the processor, so its heat dissipation efficiency is higher than that of heat pipe air conditioning technology and heat pipe back planes. The company uses loop heat pipes for heat dissipation to handle heat fluxes of up to 250W/cm2 (ordinary air cooling can only handle heat fluxes of around 10W/cm2).

Faster heat transfer rates with a two-phase cold plate cooling temperature gradient compared to single-phase cold plate

cooling. Heat pipe systems can transfer heat with a small temperature

difference without external energy and therefore have good energy efficiency

and cooling capacity, are non-intrusive to the room environment and can be

integrated with compression systems. The high reliability is due to the absence

of moving parts in the structure.

In summary, the use of phase change liquid

cooling plate technology in data centres has outstanding technical advantages

for the whole communications industry in terms of achieving energy saving and

emission reduction on a large scale and improving the utilisation rate of

server rooms, and has a broad application prospect.

As a professional heat sink design and manufacture supplier, Pioneer Thermal can provide the suitable liquid cooling plate solution based on your thermal demands.

+86-18902844286

+86-18902844286

E-mail

E-mail