This requires the heat sink to be light, thermally conductive, and malleable. Only by relying on a limited size to exert a large heat dissipation performance, can it be a true heat dissipation escort for electronic products.

So what kind of material can be selected to make a heat sink that meets the requirements in terms of dimensions and does not lose the heat dissipation effect? Let me take you to learn about several common materials used to custom heatsinks today.

1. Plastic Heat Sink

Plastic radiators have been developed and promoted in Zhejiang, Beijing, Shandong, Xi’an and other places. Common plastic heatsinks are made by filling plastic with certain metal oxide powder, carbon powder, fiber or ceramic powder to improve it. The thermal conductivity. This kind of plastic radiator is extremely light in weight, which is in line with the needs of electronic products. In addition, it has strong plasticity in appearance and low cost, which has been favored by many manufacturers.

However, compared with the heat sink made of metal alloy, its thermal conductivity is not stable, the thermal conductivity varies greatly, and it cannot be ensured that it can be perfectly adapted to the working environment. It may even deform after working for a long time. Therefore, its performance and stability are still poor needs improvement.

The chemical properties of copper are unstable, and it is difficult to react with oxygen and water in the air at room temperature. Therefore, manufacturers do not need to perform sophisticated post-processing on copper radiators to ensure that it has a long service life. Secondly, the heat dissipation capacity of copper radiators can be regarded as yes. They tend to absorb heat quickly and dissipate heat quickly. The heat dissipation capacity and corrosion resistance are both stronger than that of aluminum. Although the copper radiator has its own characteristics, the price is often very expensive, and it is generally not recommended to consider the use of this radiator if the economic conditions are limited. Moreover, the quality is very heavy and cannot meet the requirements of thinner and lighter electronic products.

Aluminum alloy is considered to be the hotter radiator manufacturing material on the market today, among which aluminum alloy 6063 and 6061 can be considered comparatively. Although the heat dissipation performance is not as good as copper, the heat dissipation coefficient can reach 201W/mK, which can meet the needs of electronic products for heat dissipation. The light weight, easy processing, beautiful appearance, and affordable characteristics make it particularly widely used.

The electronic profile radiator produced by Pioneer Thermal is made of aluminum alloy 6063/6061, and in order to make the radiator produced more decorative appearance, longer life, and stronger heat dissipation performance, multiple processing techniques are performed on the product. Through sandblasting, wire drawing and laser technology, the surface of the radiator molded is cleaner and smoother, and the decoration is strengthened. In addition to the electroplating, anodizing and baking paint processes, by adding electroplating layer, oxide layer and special material paint on the surface to improve the overall wear resistance, corrosion resistance and heat resistance of the radiator, the performance and degree of the radiator are improved. Carried out a qualitative improvement.

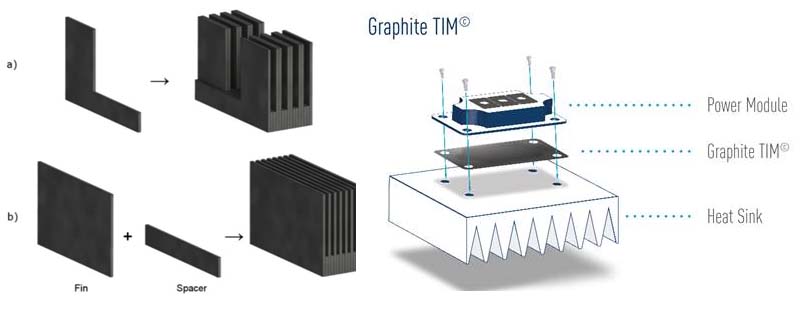

4. Graphite Heat Sink

Graphite is a new type of heat conduction and heat dissipation material. Although it is mainly made of a single carbon element, it has a thermal conductivity comparable to that of metal materials. Compared with copper and aluminum, it is lighter in weight and has more stable chemical properties. To be ultra-thin, it is indeed a very good material for making radiators. However, the price of graphite material itself is very expensive. The later processing fee and die-cutting management fee of graphite radiator are sometimes even more expensive than the material cost. Therefore, the cost of using graphite radiator is very expensive and the application is not very extensive.Today, with the development of light and thin electronic products, Pioneer Thermal Heat Sink Manufacturer strives to adapt to the development trend and adopts materials to customize electronic heatsinks. The quality is lightweight and ultra-thin, the appearance is exquisite and generous, and the heat dissipation capacity is constantly improved to provide customers with reliable products and meticulous services.

+86-18902844286

+86-18902844286

E-mail

E-mail