Aluminum is an extremely abundant metal element on the earth, ranking 2nd among the metals in terms of its reserves. Since alumina was converted into aluminum by electrolysis in 1808 in a laboratory, aluminum has been widely used in various aspects of life, military and technology through continuous technological innovation. Aluminum and its alloys have good appearance, light weight, good processing properties, physical properties, mechanical properties, as well as good corrosion resistance and good thermal conductivity, so that aluminum is used in a large number of applications in the field of heat dissipation, such as the application of communications, industry, medical, aviation, automotive, power new energy, etc.

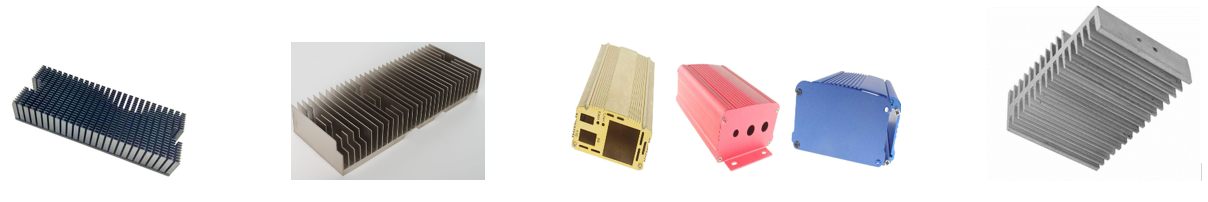

The aluminum extrusion process is to make the high temperature softened aluminum ingots flow through the aluminum extrusion model under the strong extrusion of aluminum extrusion machine to form the extrusion heatsink in accordance with the required shape. According to the use and demand of various industries, the aluminum extrusion process is recognized as a solution to maximize the cost performance of aluminum products and continues to develop.

Extruded aluminum heatsink has the following advantages:

1. Excellent thermal conductivity, because fin and the base plate do not have any contact thermal resistance, you can maximize the heat dissipation characteristics of the heat sink

2. Flexible shape design, because aluminum can be various shape at a certain temperature, you can design different structures according to different use scenarios

3. Corrosion resistance.

4. Excellent machinability

5. Excellent surface treatment characteristics, a variety of surface treatment can be applied according to customer’s requiment: paint, electroplating, polishing, and anodic oxidation

6. Very cost-effective

7. Low mold cost and short build time

8. Environmental protection without pollution

Pioneer Thermal, as a technology company that provides and manufactures heat sink solutions, is committed to continuously developing cost-effective and reliable solutions to serve our customers. In terms of technology, through joint development with the aluminum extrusion factory, the thickness of the aluminum extrusion teeth has been increased from 0.6mm to 0.3mm, which greatly increases the heat sink area in the same size structure so that the electronic components can run at the most suitable temperature continuously, improving the reliability of the product and reducing the cost to a large extent. At the same time, in order to solve the heat dissipation solution of high heat flow density, PT buries heat pipes in the aluminum extrusion and press fit the copper block etc. so that the heat of electronic components is quickly spread to the heat sink and brought into the air through the heat sink to increase the heat sink effect. Therefore, Pioneer Thermal can provide the most reliable and cost-effective heat dissipation solutions and products according to the different needs of customers. For the new energy market, PT has successfully overcome the difficulties and provided the perfect solution for large aluminum heatsink extrusion that have exceeded the limits of aluminum extrusion equipment, combined with stir friction welding technology.

As the industry continues to evolve, Pioneer Thermal provides processing services to customers around the world with perfect manufacturing processes and equipment, as well as excellent design solutions to solve customers' heat dissipation problems.

+86-18902844286

+86-18902844286

E-mail

E-mail